NEW HAMPSHIRE PRODUCTION FACILITY

Dalkia employed HVAC, controls and lighting upgrades to increase energy savings for a large manufacturer. Read more in our industrial case study.

Our Customer

Dalkia provided full energy services to a large manufacturer of electrical interconnect products at their New Hampshire production facility. Constructed in the mid 1980’s, the site features a 214,000 sqft manufacturing plant which produces printed circuit boards and other electronic equipment used in military and commercial applications.

Projects

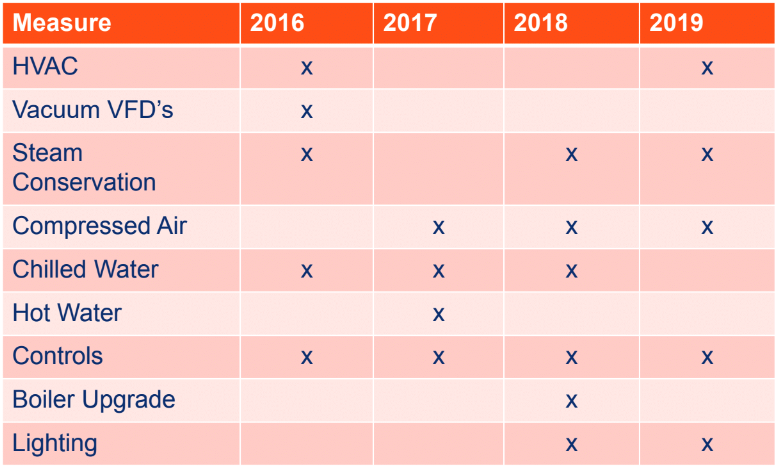

After performing a thorough energy audit, Dalkia worked closely with the client to prioritize recommended energy efficiency measures taking into account corporate savings targets, immediate needs of the plant, and available utility incentives minimizing the upfront capital required for the improvements.

The goal of phase 1 was to bring quick monetary savings to the customer, replace end-of-life equipment, and improve comfort for building occupants. Dalkia was able to secure, on the customer’s behalf, funding available from various utility incentive programs which, in the first year, covered 53% of the capital improvement costs.

In years 2-3, the customer committed nearly four times the initial investment allowing Dalkia to bring even greater savings through added energy efficiency measures. In phase 2, the site’s central plant was upgraded to improve efficiency and resiliency. Upgrades in subsequent years included a steam boiler, two air compressors, two chillers, lighting upgrades, and controls.

Looking forward, Dalkia and the client hope to build on their relationship with additional phases of work including additional HVAC, controls, and lighting upgrades, and energy managed services.

Results

Energy efficiency measures implemented in just the first year produced an annual cost saving of over $100k with a simple payback period of 1.7 years, bringing improved throughput to the manufacturing plant. In phase 2, Dalkia was able to deliver to the customer a cost savings of $530k per year with a simple payback of under 3 years, reducing annual electricity usage by 3.3 GWh/year and gas usage by 24,000 DTH/year. Over the course of the engagement, Dalkia secured $1.1M in utility incentives on behalf of the customer.